The Essential role of carrier oil in chemical manufacturing

Chemical production involves the use of a variety of parts and substances to produce a wide range of goods that support different sectors. The carrier oil is one important component that frequently goes unseen but is quite important to the procedure. Carrier oils are essential for achieving desired results since they act as a basis for various chemical formulations and as a conduit for chemical compounds.

What is Carrier Oil?

A neutral, non-volatile material originating from plants, animals, or minerals is called a carrier oil. Essential oils, perfumes, and other active compounds are diluted and transported using it for a variety of purposes. The compatibility with the target product, stability, and capacity to improve the desirable attributes of the final formulation are all taken into consideration when choosing carrier oils.

The Importance of Carrier Oils in Chemical Manufacturing

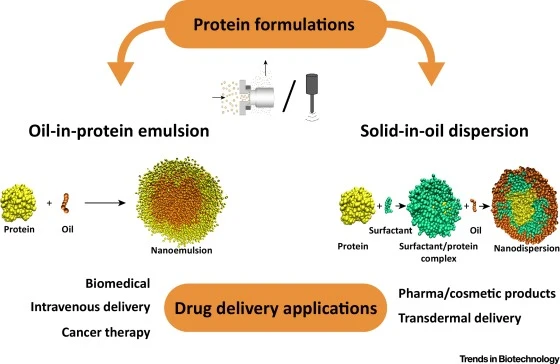

1.Solubility and Dispersion:

Carrier oils are essential for the solubilization and dispersion of other materials, which is why they are used in these processes. Both lipophilic (oil-soluble) and hydrophilic (water-soluble) substances can be dissolved or dispersed by them. A better product’s efficacy and performance are made possible by this feature, which guarantees the uniform distribution of active chemicals within it.

2.Stability and Shelf Life:

Carrier oils contribute to improved chemical formulation stability and shelf life. By serving as a barrier of defense, they stop the active substances from oxidizing, degrading, or evaporating. By doing this, it is made sure that the product will be useful and effective for a long time, giving customers reliable outcomes.

3.Control and Accuracy:

Carrier oils provide a certain amount of control and accuracy in the production of chemicals. As a result, manufacturers may produce products with the required concentrations, viscosities, and textures. They also enable precise dosing and blending of active components. The production process is more reliable and consistent thanks to this control.

4.Safety and Compatibility:

Based on their safety profile and compatibility with other components, carrier oils are chosen. They should not contain any impurities that can lower the standard of the finished product and be non-toxic, hypoallergenic, and clean. Without endangering the environment or end users, carrier oils offer a secure and dependable platform for the formulation of chemicals.

5.Enhanced functioning:

Some carrier oils have inherent qualities that improve the finished product’s functioning. For instance, some carrier oils have moisturizing or emollient qualities that make them appropriate for formulations in skincare or personal care products. These oils increase the product’s value by offering further advantages and improving the overall user experience.

Common Types of Carrier Oils in Chemical Manufacturing

Carrier oils come in a variety of forms, each with certain advantages and traits that make it useful in the production of chemicals. the following are a few frequently used carrier oils:

1.Cold-Pressed Oils:

Oils that have experienced cold pressing are either mechanically or spontaneously extracted. To extract the oil from the pulp, the clean nut, seed, fruit, or vegetable is typically crushed into a paste and then gently pressed. In order to ensure that temperatures do not rise above 80-90°F, this system strictly regulates temperature.

As a result, the oil’s beneficial components and natural state are preserved. The culinary and carrier oils that are produced using this method are some of the best in the world, despite the fact that it is not a feasible method of extraction for all vegetable oils.

2.Minerals oil:

It is well known that mineral oil has great lubricating qualities. In mechanical systems, it can be used as a lubricant to reduce friction between moving parts and stop wear and tear. Because to its low viscosity, machinery and equipment can operate more smoothly and effectively.

It is significant to remember that while mineral oil has many uses and advantages, there are other factors to take into account. For example, its petroleum-based origin raises environmental concerns, and for some purposes, there might be alternative, more sustainable solutions. Additionally, in applications involving food processing and direct contact with food, it is crucial to utilize food-grade mineral oil.

3.Conventionally Refined Oils:

Oils that have been refined conventionally use high heat and chemical solvents as the refinement procedure for ordinary cooking and carrier oils. The oils undergo deodorization and bleaching throughout these operations, which also depletes them of many healthy components.

Fully refined oils are frequently subjected to all types of refining, such as a high-heat process that can reach temperatures of 450°F, a “winterization” procedure that can expose them to temperatures as low as -30°F, chemical deodorization, and finally a final bleaching.

4.Silicone Oils:

Silicone oils are the best choice for lowering friction between moving parts because of their superior lubricating qualities. In order to provide a smooth functioning and avoid wear and tear, they can be utilized as lubricants in mechanical systems. Their low surface tension also aids in lowering drag and enhancing efficiency in a variety of applications.

![]()

Silicone oils are frequently employed in the electrical and electronic industries due to their superior electrical insulating capabilities, They offer insulation against electrical current and protection from it, avoiding short circuits and other electrical issues. Silicone oils can sustain high voltage levels because they have significant dielectric strength.Their versatility and unique characteristics make them essential in a wide range of industries, including automotive, electrical, manufacturing, and personal care.

Conclusion

Carrier oils play a crucial and important function in the production of chemicals, which should not be disregarded. They are an essential part of the formulation process and guarantee the solubility, stability, control, and compatibility of the active components. Carrier oils are essential to the success of many companies that depend on the production of chemicals because they improve the functionality and performance of the finished product.

Its wide range of applications spans industries such as automotive, cosmetics, pharmaceuticals, food processing, and more. Proper consideration of specific application requirements and regulations is necessary to ensure safe and effective use of carrier oil in various contexts.

[/fusion_text][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]

Fill the Form

Let’s Talk!

At SAKHA INTERNATIONAL, we make sure to provide the best quality of Essential Oil in the BEST prices.

We have well skilled staff who first understands the need and requirements of our customers and then refer them the product accordingly. We are the authorized stockiest/dealers of big companies.

If you want the best quality ESSENTIAL OIL with Best Price. Call us today at 9810055405/9312455405.

Leave A Comment