In today’s competitive market, product quality plays a crucial role in determining the success of a business. One key ingredient that has been revolutionizing product manufacturing is Magnesium Stearate. This article aims to shed light on the significance of Magnesium Stearate and India’s crucial role in its production.

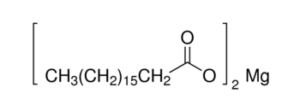

Understanding Magnesium Stearate

Magnesium stearate is a compound composed of magnesium and stearic acid. It is a fine, white powder primarily used as a lubricant and flow agent in various industries. Its unique properties make it an indispensable component in a wide range of applications.

Magnesium stearate possesses several excellent properties that make it highly desirable in manufacturing of various products.

Applications of Magnesium Stearate in Various Industries

Pharmaceutical industry

Magnesium Stearate plays a vital role in the pharmaceutical industry as an excipient, ensuring the proper formulation and stability of medications. It aids in the smooth manufacturing of tablets and capsules, preventing them from sticking to the production machinery.

Furthermore, magnesium stearate improves dissolution and bioavailability of active pharmaceutical ingredients, ultimately enhancing the therapeutic effectiveness of drugs.

Food industry

Within the food industry, Magnesium Stearate serves as a valuable food additive.

Its addition to food products enhances stability and increases their shelf life. Moreover, it improves the texture and consistency of various food items, resulting in a pleasant sensory experience for consumers.

Cosmetics industry

In the cosmetics industry, Magnesium Stearate finds wide applications. It is used for its binding properties, contributing to the consistent texture and performance of cosmetic formulations.

Additionally, Magnesium Stearate imparts a smooth and creamy texture to cosmetic products and enhances their longevity.

Other industries

Apart from its applications in the pharmaceutical, food, and cosmetics sectors, magnesium stearate also finds utility in other industries. For instance, in plastics and rubber manufacturing, it acts as a lubricant and mold release agent, ensuring seamless production processes.

Furthermore, it offers excellent heat stability, making it an ideal ingredient in lubricants and additives.

India’s Dominance in Magnesium Stearate Production

India’s Magnesium Stearate production capacity

India has emerged as a global leader in magnesium stearate production, with a significant production capacity. Several state-of-the-art manufacturing facilities equipped with advanced technology contribute to India’s overall dominance in this sector. The country’s production capabilities ensure a steady supply of high-quality magnesium stearate to meet both domestic and global demands.

Factors contributing to India’s success in magnesium stearate production

Several factors drive India’s success in magnesium stearate production. The country benefits from an abundant supply of raw materials, ensuring uninterrupted production. Additionally, India’s skilled workforce and adherence to stringent quality control measures guarantee the production of superior-grade magnesium stearate. Furthermore, the government’s favorable policies and initiatives have fostered the growth of the magnesium stearate industry.

Global demand and India’s position as a major exporter

Given the versatile applications of magnesium stearate, the global demand for this compound continues to soar. India has capitalized on this demand and emerged as a major exporter of magnesium stearate. Its reputation for producing high-quality magnesium stearate has allowed the country to establish strong trade relationships with various nations, further boosting its position in the global market.

Breaking Barriers: How Magnesium Stearate Enhances Product Quality

Improving dissolution and bioavailability in pharmaceuticals

Magnesium stearate’s lubricating properties significantly improve the dissolution and bioavailability of pharmaceuticals. By reducing friction between particles, it promotes uniform distribution and dissolution of active ingredients in the body, enhancing the therapeutic effects of medications.

Texture enhancement and stability in food products

In the food industry, magnesium stearate plays a crucial role in enhancing texture and stability. It acts as a natural emulsifier, ensuring the smooth incorporation of ingredients and preventing separation. Additionally, its lubricating properties contribute to a consistent and desirable texture, thereby improving the overall quality of food products.

Enhancing formula consistency and performance in cosmetics

Cosmetic manufacturers rely on magnesium stearate to enhance formula consistency and product performance. Due to its binding properties, it promotes homogeneous mixing of ingredients, maintaining a consistent texture throughout the manufacturing process. This attribute ensures that cosmetic products maintain their desired properties, giving users a consistent experience.

Advancements in Magnesium Stearate Technology

Innovations in magnesium stearate manufacturing processes

The magnesium stearate industry has witnessed remarkable technological advancements, leading to more efficient and sustainable manufacturing processes. Innovations in purification techniques and production equipment have resulted in higher purity levels and reduced environmental impact. Additionally, continuous research and development efforts aim to further optimize the production process, ensuring the highest quality magnesium stearate.

Emerging applications of magnesium stearate in specialized industries

As technology continues to advance, new applications for magnesium stearate are being discovered. Specialized industries such as nanotechnology and advanced materials are exploring the use of magnesium stearate for its unique properties, taking advantage of its lubricating and stabilizing capabilities.

Magnesium stearate alternatives and their potential impact

While magnesium stearate has numerous benefits, ongoing research focuses on developing alternatives that can provide similar advantages with potentially improved characteristics. These alternatives aim to address any concerns related to allergies or specific product requirements, offering flexibility and choice to manufacturers.

Quality Control Challenges and Solutions

Common quality concerns with magnesium stearate

Like any manufacturing process, magnesium stearate production is not without its challenges. Quality concerns may arise, such as variations in particle size, impurities, or inadequate lubrication properties. However, addressing these concerns through rigorous quality control measures ensures consistent and reliable magnesium stearate production.

Strategies to ensure high-quality magnesium stearate production

To ensure high-quality magnesium stearate production, manufacturers employ various strategies. These include rigorous testing and analysis of raw materials, implementing robust purification processes, and meticulous monitoring of production parameters. Furthermore, adherence to industry-specific regulations and certifications guarantees the highest standards of quality.

Regulatory factors and compliance in magnesium stearate manufacturing

The manufacturing of magnesium stearate is subject to regulatory oversight, with strict guidelines to ensure consumer safety and product quality. Compliance with Good Manufacturing Practices (GMP) and adherence to relevant international standards form a crucial part of magnesium stearate production. Manufacturers must meet stringent regulatory requirements to maintain a strong reputation and market position.

Future Outlook for Magnesium Stearate Industry

Growth trends and projections

The magnesium stearate industry is poised for significant growth in the coming years. With expanding applications across diverse sectors, the demand for magnesium stearate is projected to rise steadily. As industries continually seek innovative solutions, the reliance on magnesium stearate will only increase, fueling the growth of the industry.

Technological advancements shaping the industry

Advancements in technology and manufacturing processes continue to shape the magnesium stearate industry. From improved purification methods to sustainable production practices, technological innovations drive efficiency, quality, and environmental sustainability. Embracing these advancements will ensure that the industry remains at the forefront of progress.

Potential challenges and opportunities

While the future of the magnesium stearate industry appears promising, challenges and opportunities lie ahead. Increasing competition, evolving regulatory frameworks, and changing consumer preferences present challenges that manufacturers must navigate. However, embracing the potential for innovation and diversification opens doors for new applications, partnerships, and growth opportunities.

Summary

In summary, magnesium stearate is a crucial component in diverse industries due to its exceptional properties and versatility. With India’s dominance in magnesium stearate production, the country has solidified its position as a major contributor to the global market. The impact of magnesium stearate on product quality is substantial, from enhancing dissolution in pharmaceuticals to improving stability in food and cosmetics. Embracing technological advancements and adhering to stringent quality control measures continue to propel the industry forward. The future outlook for the magnesium stearate industry is promising, with growth potential and opportunities on the horizon.

Frequently Asked Questions (FAQs)

What are the common applications of magnesium stearate?

Magnesium stearate is widely used in the pharmaceutical, food, cosmetics, plastics, rubber, and lubricant industries. Its applications range from enhancing the manufacturing processes of tablets and capsules to improving texture and stability in food products. Moreover, it plays a vital role in cosmetics, imparting consistency and enhancing performance.

How does magnesium stearate enhance product quality?

Magnesium stearate enhances product quality through various mechanisms. In pharmaceuticals, it improves dissolution and bioavailability, ensuring adequate therapeutic effects. In food products, it contributes to a desirable texture, enhances stability, and extends shelf life. Furthermore, in cosmetics, magnesium stearate ensures homogeneous mixing and consistency, resulting in superior formula performance.

What are the challenges in magnesium stearate production control?

Control over magnesium stearate production faces challenges related to variations in particle size, impurities, and lubrication properties. However, implementing rigorous quality control measures, including testing raw materials, applying purification processes, and monitoring production parameters, helps address these concerns and ensures high-quality production.

What is the future outlook for the magnesium stearate industry?

The magnesium stearate industry shows promising growth prospects. With increasing demand and expanding applications, the industry is projected to experience steady growth. Technological advancements and compliance with regulations will shape the industry’s future, with opportunities for innovation, partnerships, and market expansion on the horizon.

[/fusion_text][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]

Fill the Form

Let’s Talk!

At SAKHA INTERNATIONAL, we make sure to provide the best quality of Magnesium Stearate in the BEST prices.

We have well skilled staff who first understands the need and requirements of our customers and then refer them the product accordingly. We are the authorized stockiest/dealers of big companies.

If you want the best quality Magnesium Stearate with Best Price. Call us today at 9810055405/9312455405.

Leave A Comment