Enhancing Footwear Durability with Zinc Oxide Reinforcement

Footwear durability is a crucial consideration for both manufacturers and consumers. Shoes that withstand wear and tear, particularly in their soles and structural components, are highly sought after. Among the various advancements in material science, the integration of zinc oxide in footwear manufacturing has emerged as a game-changer, elevating the durability and strength of shoes, especially in the context of rubber soles and other structural components.

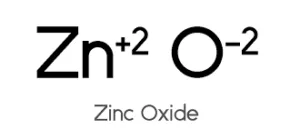

The Role of Zinc Oxide

Zinc Oxide, a multifunctional compound long recognized for its diverse applications, has found its way into the footwear industry due to its unique properties. When incorporated into shoe materials, especially in rubber soles, zinc oxide acts as a reinforcing agent, significantly bolstering the shoe’s structural integrity and wear resistance.

Footwear Durability – Understanding Zinc Oxide’s Contribution

Improved Strength and Sturdiness:

Zinc oxide particles, when added to the rubber used for shoe soles, enhance the material’s tensile strength. This reinforcement minimizes the likelihood of cracks, tears, or deformities, thereby ensuring a sturdier foundation for the shoe.

Enhanced Wear Resistance:

The incorporation of zinc oxide in rubber soles fortifies the material against abrasion and friction. This results in increased resistance to wear, ensuring that the soles retain their integrity for a longer period, even in harsh conditions.

Application in Rubber Soles

Manufacturing Process

In the manufacturing of shoe soles, zinc oxide is often introduced during the compounding stage. These tiny particles are carefully mixed into the rubber matrix, forming a cohesive blend that is then shaped into soles through various molding and curing processes. The presence of zinc oxide in the rubber matrix significantly enhances the overall quality and durability of the soles.

Impact on Wear Resistance

Zinc oxide reinforcement substantially improves the sole’s wear resistance. This is particularly crucial as the soles bear the brunt of impact, friction, and contact with various surfaces during everyday use. The enhanced wear resistance due to zinc oxide integration prolongs the sole’s lifespan, reducing the need for frequent replacements and ensuring a longer-lasting, more durable shoe.

Other Structural Components

Beyond rubber soles, zinc oxide’s application extends to other structural elements within footwear. It is integrated into various components such as midsoles, heel counters, or toe caps to reinforce and fortify these critical areas. This reinforces the overall structure of the shoe, ensuring that it maintains its shape and strength under stress.

Zinc Oxide is also widely used in footwear industry to control the odor.

Conclusion

Incorporating zinc oxide into footwear materials, particularly in rubber soles and other structural components, plays a pivotal role in significantly enhancing durability and strength. The reinforcement provided by zinc oxide effectively combats wear and tear, elevating the lifespan and performance of shoes. As the footwear industry continues to advance, this innovation stands as a testament to the commitment to producing shoes that endure and outperform expectations in durability, comfort, and reliability.

Zinc oxide’s role in improving wear resistance remains a remarkable leap forward in the quest for long-lasting and robust footwear that caters to the demands of the modern consumer.

Fill the Form

Let’s Talk!

We have well skilled staff who first understands the need and requirements of our customers and then refer them the product accordingly. We are the authorized stockiest/dealers of big companies.

If you want the best quality ZINC OXIDE at least possible process Call us today at 9810055405/9312455405.

[…] It strengthens shoe fabrics, acting as the spinach to your shoe’s Popeye, enhancing durability and […]