Masterbatch formulations form the backbone of modern polymer processing, enabling manufacturers to incorporate pigments, additives, and performance-enhancing agents into plastics in a controlled, cost-effective manner. From vibrant colorants in consumer goods to functional additives in industrial components, masterbatches ensure consistent dispersion and performance across diverse applications. However, achieving optimal processing and performance often hinges on the use of the right auxiliary additives. Among these, zinc stearate has emerged as a veritable game-changer—transforming how masterbatches are processed, enhancing end-product quality, and unlocking new possibilities in polymer engineering.

In this blog post, we will discuss in-depth the chemistry, science and functionality of stearate as talked about by Sakha International, explore its important roles in masters formulation, and shed light on why it has become indispensable for manufacturers to optimize production efficiency and product performance.

Why Zinc Stearate is a Game-Changer for Masterbatch Formulations

Zinc Stearate has earned its place as a critical additive in masterbatch formulations due to its ability to act as a lubricant, dispersing agent, and processing aid. It supports the uniform distribution of pigments and additives in the base polymer, ensuring a more stable, efficient, and high-performing product.

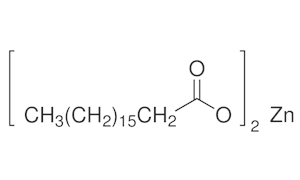

What is Zinc Stearate and How is it Made?

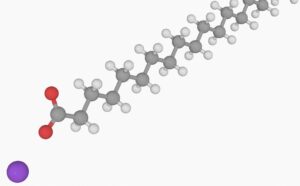

Zinc Stearate is a zinc salt of stearic acid, typically produced through the reaction of stearic acid with zinc oxide. It’s a fine, white powder that is hydrophobic, non-toxic, and insoluble in water but soluble in aromatic hydrocarbons and chlorinated hydrocarbons when heated.

Because of its unique chemical properties, Zinc Stearate finds use not only in masterbatch production but also in cosmetics, pharmaceuticals, rubber, and even paints.

Understanding Masterbatch Formulations

Before diving into the specifics of Zinc Stearate, it is essential to understand what masterbatches are and their role in polymer processing.

A masterbatch is a concentrated mixture of pigments, additives, or fillers encapsulated during a heat process into a carrier resin. It is used to color or impart other properties to plastics. The masterbatch is then cooled and cut into granular shapes, making it easy to handle and dose during manufacturing.

Masterbatches are widely used in:

-

Injection molding

-

Blow molding

-

Extrusion

-

Film blowing

-

Thermoforming

They provide better dispersion of additives and colorants compared to directly mixing raw pigments or additives with polymer resins, ensuring consistent quality and reducing waste

Physical and Chemical Properties of Zinc Stearate

Zinc Stearate is known for its:

-

Low melting point (around 120–130°C)

-

High lubricity

-

Hydrophobic nature

-

Good thermal resistance

-

High opacity

These properties make it ideal for thermoplastic processing, where temperature sensitivity and lubrication are key.

Lubrication Advantages in Polymer Processing

Zinc Stearate acts as a processing lubricant, reducing friction between polymer chains and machinery. This facilitates:

-

Smoother extrusion

-

Less wear on equipment

-

Reduced processing time

-

Lower energy consumption

As a result, production costs go down while efficiency goes up.

Dispersing Agent Role in Masterbatch

One of the standout roles of Zinc Stearate is as a dispersing agent. It ensures that additives and pigments are uniformly distributed throughout the polymer matrix, which leads to:

-

Better color consistency

-

Fewer defects

-

Improved product performance

This is crucial in applications where visual appearance and structural integrity matter.

How Zinc Stearate Enhances Color Dispersion

Color dispersion is key in any masterbatch. Uneven color means inconsistent quality, which can damage brand reputation. Zinc Stearate promotes better pigment wetting and flowability, especially in highly pigmented formulations. It acts as a bridge between the pigment particles and the polymer matrix, ensuring vibrant, uniform coloration.

Anti-blocking and Mold Release Capabilities

Zinc Stearate’s unique structure also gives it anti-blocking properties, preventing plastic sheets or films from sticking to each other. It also serves as an internal mold release agent, reducing the need for external release sprays and improving product finish, especially in injection molding.

Zinc Stearate vs Calcium Stearate: Which is Better for Masterbatch?

While both Zinc and Calcium Stearates are commonly used, Zinc Stearate offers better performance in:

-

Color dispersion

-

Heat resistance

-

Moisture repelling

Calcium Stearate, while less expensive, may not deliver the same results in demanding processing conditions, particularly where high thermal stability or color brilliance is needed.

Comparing Organic and Metallic Stearates in Formulations

Metallic stearates like Zinc and Calcium stearate differ from organic stearates primarily in terms of thermal stability and compatibility with polymers. Zinc Stearate, as a metallic stearate, offers:

-

Higher process control

-

Better lubricant properties

-

More robust chemical resistance

This makes it the preferred choice for engineering plastics and high-performance masterbatch applications.

Improving Processability and Output Quality

By acting as both a lubricant and dispersant, Zinc Stearate directly enhances:

-

Melt flow index

-

Surface finish

-

Dimensional accuracy

This means products not only look better but also perform more reliably in end-use applications.

Applications of Zinc Stearate in Plastic and Rubber Industries

Industries using polyethylene (PE), polypropylene (PP), and polystyrene (PS) benefit immensely from Zinc Stearate. Applications include:

-

Film extrusion

-

Injection molding

-

Sheet and pipe manufacturing

-

Rubber vulcanization

Its multifunctional benefits reduce the need for multiple additives, simplifying formulation while cutting costs.

Common Formulation Challenges and How Zinc Stearate Solves Them

Challenges like poor pigment dispersion, machine wear, uneven melt flow, and surface defects are all common in masterbatch processing. Zinc Stearate addresses these with its:

-

Excellent lubrication

-

Anti-static behavior

-

Compatibility with a wide range of polymers

This makes it a go-to additive for solving technical formulation problems.

Real Industry Examples: Success with Zinc Stearate

Many plastic manufacturing companies report up to 15% improvement in productivity and 30% reduction in defective output after switching to Zinc Stearate-based formulations. One case study from a European film extrusion plant showed enhanced gloss, reduced static cling, and better roll handling after implementation.

Innovations and Evolving Uses in Polymer Technology

Zinc Stearate is finding new life in nanocomposite development, biodegradable plastics, and advanced coloring systems. Its compatibility with 3D printing filaments and bio-based polymers is also being actively explored by material scientists.

Final Thoughts: The Game-Changing Role of Zinc Stearate

Zinc Stearate is more than just a filler—it’s a transformative component in masterbatch formulations. It plays a multi-dimensional role as a lubricant, dispersant, heat stabilizer, and anti-block agent, solving real-world manufacturing problems and improving end-product performance.

With growing focus on performance, sustainability, and cost-efficiency in plastics, Zinc Stearate proves itself to be an indispensable additive that delivers real results across industries.

Whether you’re optimizing an old formulation or launching a new product line, Zinc Stearate could be the key to unlocking better quality, higher efficiency, and greater profitability.

We are the leading wholesale supplier of best Zinc Stearate

Buy Zinc Stearate in bulk from SAKHA INTERNATIONAL for your business. Contact us at 👉 9810055405.

Leave A Comment