Ethylene Vinyl Acetate (EVA) sheets have found widespread application in a variety of industries due to their flexibility, toughness, clarity, and resistance to UV radiation and stress-cracking. Whether used in solar panel encapsulation, footwear, packaging, or sports equipment, EVA materials are often enhanced with various additives to improve performance. One such additive that has garnered considerable attention is zinc stearate. Although it might seem like a simple compound, zinc stearate plays a vital role in enhancing the processing, performance, and durability of EVA sheets.

In this blog post, Sakha International guides you as we explore the top benefits of using zinc stearate in EVA sheets, examining its chemical properties, functional roles, and the advantages it offers to manufacturers and end-users alike.

What is Zinc Stearate?

Zinc stearate is a zinc soap, a chemical compound derived from the reaction of zinc oxide and stearic acid. It is commonly used in various industries due to its lubricating, anti-caking, and release agent properties. In the context of polymers and plastics, zinc stearate is used as a processing aid, lubricant, and mold release agent.

Its hydrophobic nature and low melting point (around 120–130°C) make it especially valuable in thermoplastic applications, where it enhances flow characteristics and prevents materials from sticking to processing equipment.

Overview of EVA Sheets

EVA (Ethylene Vinyl Acetate) is a copolymer of ethylene and vinyl acetate. The vinyl acetate content usually ranges from 10% to 40%, influencing the material’s flexibility and clarity. EVA sheets are valued for properties such as:

-

Elasticity and softness

-

Impact and stress crack resistance

-

Low-temperature toughness

-

Optical clarity

-

UV resistance (especially in solar applications)

However, to optimize processing and end-use performance, additives such as crosslinking agents, UV stabilizers, and lubricants like zinc stearate are incorporated into EVA formulations.

Top Benefits of Zinc Stearate in EVA Sheets

1. Excellent Internal and External Lubrication

One of the foremost advantages of using zinc stearate in EVA sheet production is its exceptional lubricating properties. During processing, EVA compounds need to pass through extruders and molds. Zinc stearate helps in reducing friction both internally (within the polymer matrix) and externally (against machinery surfaces).

Benefits:

-

Enhances material flow during extrusion and molding

-

Reduces torque and wear on machinery

-

Enables higher processing speeds

-

Minimizes energy consumption during manufacturing

2. Improved Mold Release

EVA materials, due to their tacky nature at processing temperatures, often pose challenges when being removed from molds. Zinc stearate acts as an effective mold release agent, forming a thin, non-stick layer on mold surfaces.

Benefits:

-

Prevents sticking of EVA sheets to molds

-

Reduces surface defects and tearing during demolding

-

Enhances surface finish of the final product

-

Minimizes cleaning and maintenance of molds

This property is particularly crucial in the footwear and packaging industries where surface appearance and dimensional precision are essential.

3. Enhanced Dispersion of Fillers and Pigments

Zinc stearate significantly improves the dispersion of fillers, stabilizers, and pigments in EVA compounds. A uniform dispersion ensures consistent quality and appearance throughout the product.

Benefits:

-

Uniform color distribution in pigmented EVA sheets

-

Homogeneous material structure

-

Improved physical and mechanical properties

-

Reduction in agglomeration or clumping of fillers

This is especially valuable in decorative and visually appealing applications like colorful EVA foams and mats.

4. Thermal Stability and Processing Efficiency

EVA sheets are often processed at high temperatures, where additives can degrade or react undesirably. Zinc stearate provides moderate thermal stability, helping to maintain the integrity of the polymer matrix and minimizing degradation during processing.

Benefits:

-

Extends the processing window

-

Prevents premature crosslinking

-

Maintains desired melt flow rate

-

Enhances the longevity of the finished product

This ensures consistent quality in large-scale, continuous production environments.

5. Acts as a Heat Stabilizer in Combination with Other Additives

Though not a primary heat stabilizer on its own, zinc stearate often functions synergistically with other stabilizers like calcium stearate and antioxidants. When used in combination, it helps to neutralize acidic residues, especially in vinyl-based systems.

Benefits:

-

Prevents degradation of the polymer backbone

-

Enhances color stability of EVA sheets

-

Reduces yellowing and discoloration under heat

-

Improves compatibility with crosslinking agents

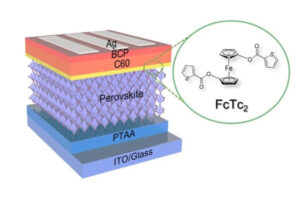

Such stability is especially important in applications like EVA solar encapsulants, where long-term UV and thermal resistance is critical.

6. Cost-Effectiveness

Zinc stearate is a relatively low-cost additive, especially when compared to other specialty processing aids and stabilizers. Its multifunctional nature (lubricant, release agent, stabilizer, dispersant) means that it can replace multiple additives, reducing overall formulation complexity and cost.

Benefits:

-

Reduces the number of additives required

-

Minimizes procurement and inventory management costs

-

Improves formulation efficiency

-

Enhances return on investment for manufacturers

For price-sensitive applications like foam sheets, slippers, and yoga mats, zinc stearate delivers exceptional value.

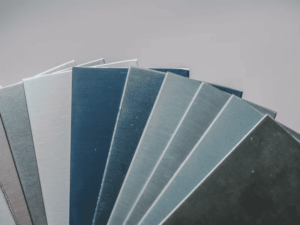

7. Improved Surface Finish and Aesthetics

The presence of zinc stearate leads to smooth surface finish and enhanced gloss on EVA sheets, especially in applications where visual appeal matters.

Benefits:

-

Smooth, uniform surface texture

-

Enhanced visual and tactile quality

-

Better printability and lamination adhesion

-

Reduces the occurrence of surface blemishes or pinholes

This is particularly important in consumer products like flip-flops, toys, and floor mats.

8. Enhancement in Foam Quality for EVA Foams

In foam applications, zinc stearate contributes to controlled cell structure and uniform foaming, a crucial factor in producing high-quality EVA foams.

Benefits:

-

Promotes uniform cell size and distribution

-

Enhances resilience and elasticity of foam

-

Reduces foam collapse or shrinkage

-

Improves shock absorption and cushioning properties

This is highly beneficial in the footwear industry, where comfort, durability, and appearance of foam soles are paramount.

9. Non-Toxic and Environmentally Safer Option

Zinc stearate is generally recognized as safe and non-toxic, making it suitable for applications that involve skin contact or usage in child-friendly products.

Benefits:

-

Non-irritant and skin-safe

-

Meets regulatory standards for safety (RoHS, REACH, etc.)

-

Suitable for toy and medical-grade EVA applications

-

Reduced environmental and workplace hazard risks

This makes it an eco-friendly choice compared to heavy-metal-based stabilizers and release agents.

10. Compatibility with Crosslinking Agents

EVA sheets are often crosslinked using organic peroxides or other crosslinking systems to improve mechanical and thermal properties. Zinc stearate does not interfere with most crosslinking agents and, in some cases, enhances the crosslinking process by improving dispersion and reducing localized overheating.

Benefits:

-

Even crosslink density throughout the sheet

-

Improved dimensional stability

-

Enhanced tensile and tear strength

-

Resistance to heat shrinkage

This is particularly important for EVA sheets used in solar panel encapsulation, where performance reliability over decades is non-negotiable.

Applications Enhanced by Zinc Stearate in EVA Sheets

Let’s take a look at some real-world applications where zinc stearate adds tangible value:

1. Solar Panel Encapsulation

-

Enhances clarity and stability

-

Reduces gel content

-

Improves layer adhesion and UV resistance

2. Footwear Manufacturing

-

Facilitates complex mold shapes

-

Reduces sticking and cycle time

-

Improves surface finish

3. Packaging Films

-

Provides better pigment dispersion

-

Reduces blocking and tackiness

-

Improves gloss and printability

4. Foam Products

-

Assists in uniform cell formation

-

Prevents plate-out on molds

-

Enhances tactile properties

Considerations and Best Practices

While zinc stearate offers many advantages, it must be used correctly:

-

Dosage is key: Typical loading ranges from 0.5% to 2% depending on the formulation.

-

Processing temperature should be optimized to prevent volatilization or degradation.

-

Compatibility testing is essential when using with other additives or new grades of EVA.

Overuse can lead to issues such as:

-

Slippery surfaces in footwear or floor tiles

-

Incompatibility with printing inks or adhesives

Thus, formulation balance and testing are critical for achieving the desired outcome.

Conclusion

Zinc stearate is far more than a simple additive. In the world of EVA sheets, it serves as a multifunctional agent that enhances processing, improves product quality, and reduces manufacturing costs. From solar encapsulation to sports gear and packaging, its benefits span across various high-performance applications.

As material science continues to evolve, the importance of intelligent additive selection—like the inclusion of zinc stearate—will only grow. By understanding the advantages it offers, manufacturers can not only improve product performance but also gain a competitive edge in cost and sustainability.

We are the leading wholesale supplier of best Zinc Stearate

Buy Zinc Stearate in bulk from SAKHA INTERNATIONAL for your business. Contact us at 👉 9810055405.

Leave A Comment