WHAT MAKES SAKHA INTERNATIONAL THE LEADING

BULK SUPPLIER OF MAGNESIUM STEARATE IN INDIA

MAGNESIUM STEARATE : A Comprehensive Guide for Buyers

Magnesium Stearate, a widely used substance, finds its applications across various industries. Composed of magnesium and stearic acid, this versatile compound plays a crucial role in industrial processes.

From pharmaceuticals and food production to cosmetics and plastics manufacturing, magnesium stearate showcases its functionality and significance across multiple sectors.

👉 Introduction to Magnesium Stearate

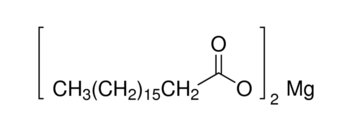

What is Magnesium Stearate?

Magnesium Stearate is a compound composed of magnesium and stearic acid. It is a fine, white powder primarily used as a lubricant and flow agent in various industries.

Its unique properties make it an indispensable component in a wide range of applications.

Production of Magnesium Stearate

Firstly, stearic acid, derived from plant or animal sources, undergoes a reaction with magnesium salts. This reaction yields magnesium stearate, which is carefully purified to ensure its optimal quality and purity.

Key properties and characteristics of Magnesium Stearate

Magnesium Stearate possesses several notable properties that make it highly desirable in manufacturing.

It boasts excellent lubricating abilities, which facilitate the smooth flow of materials during production processes. Additionally, it offers stability, non-toxicity, and compatibility with other substances, further enhancing its appeal.

👉 Wide Use of Magnesium Stearate in India

1️⃣ Magnesium Stearate in the Pharmaceutical Industry

✔️ Role of Magnesium Stearate in Medicinal Tablet Production

In the pharmaceutical industry, Magnesium Stearate acts as a crucial excipient in tablet manufacturing.

Its main function is ensuring efficient compression of powders into solid tablets by reducing friction between the tablet components.

Magnesium Stearate’s lubricating properties enable smooth tablet production, facilitating the formation of uniform and sturdy tablets.

✔️ Enhancing Drug Bioavailability with Magnesium Stearate

Besides its role in tablet formulation, Magnesium Stearate also aids in enhancing drug bioavailability.Its hydrophobic nature prevents drug dissolution, thus facilitating controlled release of active pharmaceutical ingredients (APIs) within the body.

By modulating the rate of drug absorption, magnesium stearate contributes to improving therapeutic effects and patient compliance.

2️⃣ Magnesium Stearate in the Food Industry

✔️ Functionality of Magnesium Stearate as a Food Additive

As a food additive, Magnesium Stearate serves multiple functions, ranging from emulsification to improving texture and stability.

Due to its hydrophobic nature, it assists in the uniform distribution and stabilization of oils and fats in food products. This attribute makes it valuable in various food processing applications.

✔️ Applications in Food Processing: Emulsification and Texture Enhancement

In the food industry, Magnesium Stearate finds application in emulsification processes, allowing the blending of ingredients that do not naturally mix well.

Additionally, due to its anti-caking properties, it enhances texture by preventing clumping or lump formation in powdered food products, ensuring a smooth and consistent eating experience.

3️⃣ Magnesium Stearate in the Cosmetics and Personal Care Industry

✔️ Magnesium Stearate as a Key Ingredient in Cosmetic Formulations

Within the cosmetics and personal care industry, Magnesium Stearate plays a pivotal role as an ingredient in various formulations.

Its ability to act as a binding agent and stabilizer helps maintain the integrity of cosmetics, such as pressed powders, by preventing them from crumbling or breaking.

✔️ Improving Texture and Stability in Personal Care Products

Magnesium Stearate enhances the texture and stability of personal care products like creams, lotions, and foundations.

Its lubricating properties aid in the smooth application of these products, providing a desirable sensory experience for the user.

Additionally, it contributes to the stability of emulsions, preventing phase separation and extending the product’s shelf life.

4️⃣ Magnesium Stearate in the Plastics and Rubber Industry

✔️ Role of Magnesium Stearate as a Lubricant in Polymer Production

The plastics and rubber industry benefits from the lubricating properties of Magnesium Stearate. During polymer processing, it acts as a lubricant, reducing friction between polymer chains and processing equipment. This lubrication enhances the flow properties of polymers, resulting in improved processing efficiency and facilitating the creation of complex shapes and structures.

✔️ Enhancing Processing Efficiency and Mold Release Properties

Magnesium Stearate enhances processing efficiency by reducing the adhesion of molten polymers to processing tools.

Its mold release properties enable easy demolding, ensuring smooth production processes in industries such as injection molding and extrusion. This attribute significantly contributes to increased productivity and cost-effective production.

5️⃣ Magnesium Stearate in the Paints and Coatings Industry

✔️ Utilizing Magnesium Stearate as a Rheology Modifier in Paints

In the paints and coatings industry, Magnesium Stearate finds usage as a rheology modifier. By adjusting the paint’s flow characteristics, it helps maintain a stable and consistent viscosity, facilitating easy application and preventing sagging or dripping.

✔️ Anti-Settling Effects and Improved Lack of Flooding in Coating Applications

Magnesium Stearate also exhibits anti-settling effects in coatings, preventing pigments and fillers from settling at the bottom of containers or on surfaces. This attribute enhances the coating’s overall appearance and improves the lack of flooding, ensuring an even distribution of materials on the target surface.

6️⃣ Magnesium Stearate in the Medical Devices Industry

✔️ Mold Release Properties in Medical Device Manufacturing

The medical devices industry benefits from Magnesium Stearate due to its mold release properties.

During the manufacturing process, it aids in the smooth extraction of intricate medical device components from molds. This attribute enables efficient production, improving productivity and reducing the risk of component damage.

✔️ Enhancing Quality and Consistency of Medical Implants

Magnesium Stearate plays a vital role in ensuring the quality and consistency of medical implants. By facilitating the successful release of implants from molds or other production equipment, it helps maintain the integrity and dimensional accuracy of these critical medical devices.

7️⃣ Magnesium Stearate in the Agricultural Industry

✔️ Applications in Crop Protection Products

The agricultural industry utilizes Magnesium Stearate in various crop protection products such as herbicides and fungicides. It acts as an inert ingredient that aids in the dispersion and effectiveness of active ingredients on plants.

Magnesium stearate ensures uniform coverage and adhesion of agrochemicals, maximizing their performance.

✔️ Role in Controlled Release Fertilizers

Magnesium Stearate contributes to the production of controlled-release fertilizers by acting as a coating agent.

It helps encapsulate the fertilizer particles, enabling a gradual release of nutrients into the soil. Controlled-release fertilizers with magnesium stearate coatings ensure sustainable nutrient availability for plants, reducing environmental impacts.

8️⃣ Magnesium Stearate in the Textile Industry

✔️ Improving Fiber Lubrication and Yarn Handling

In the textile industry, Magnesium Stearate finds application in fiber lubrication and yarn handling. Its lubricating properties help reduce friction between fibers, facilitating smoother yarn production processes.

By minimizing breakage and improving yarn strength, magnesium stearate promotes efficient textile manufacturing.

✔️ Anti-Bacterial Properties in Textile Production

Magnesium Stearate’s antimicrobial properties make it valuable in textile production.

It helps inhibit the growth of bacteria and other microorganisms on textile surfaces, improving hygiene and reducing the risk of unpleasant odors. This attribute finds significance in applications such as medical textiles and sportswear, where antimicrobial properties are desired.

✔️ Minimizing Static Electricity Generation

Another benefit of using Magnesium Stearate in the textile industry is its ability to minimize static electricity generation.

By reducing static charges, it prevents issues such as fabric clinging, static shocks, and dust attraction, contributing to enhanced comfort and improved overall textile quality.

9️⃣ Magnesium Stearate in the Automotive Industry

✔️ Automotive Coatings for Corrosion Protection

The automotive industry utilizes Magnesium Stearate in coatings to provide corrosion protection.

As a key ingredient, it forms a barrier on metal surfaces, shielding them against moisture and environmental damage.

Magnesium Stearate enhances the durability and lifespan of automotive components, increasing their resistance to corrosion and preserving their appearance.

✔️ Reducing Friction in Plastic Components for Enhanced Performance

Magnesium Stearate reduces friction in plastic components used in automobiles, resulting in enhanced performance.

By acting as a lubricant, it minimizes wear and tear, facilitating smoother movements and reducing noise. This attribute improves the overall efficiency and longevity of automotive systems and mechanisms.

1️⃣0️⃣ Magnesium Stearate in the Building and Construction Industry

✔️ Fire Retardant Applications in Construction Materials

In the building and construction industry, Magnesium Stearate is used as a fire retardant in construction materials. Its incorporation in products such as paints, sealants, and coatings enhances their fire resistance, thus providing greater safety in buildings. Magnesium stearate reduces the flammability and combustibility of materials, mitigating fire-related risks.

✔️ Enhancing Mechanical Properties of Polymer Materials in Buildings

This Metallic Stearate contributes to the enhancement of mechanical properties in polymer-based construction materials.

By improving the structure and integrity of these materials, it increases their strength, durability, and resistance to various environmental factors. This attribute ensures the reliability and longevity of structures, minimizing maintenance costs.

✔️ Adhesive and Sealant Production

By functioning as a lubricant, Magnesium Stearate facilitates the smooth application of these materials, ensuring optimal bonding and sealing properties.

Magnesium stearate‘s presence in adhesive and sealant formulations enhances their workability and overall performance.

1️⃣1️⃣ Magnesium Stearate in the Electronics Industry

✔️ Anti-Static Properties for Electronic Components and Devices

In the electronics industry, Magnesium Stearate’s anti-static properties make it crucial for ensuring the integrity of electronic components and devices.

It helps prevent electrostatic discharge (ESD) that can damage sensitive circuits and components.

Proper grounding and utilization of anti-static packaging, incorporating Magnesium Stearate, ensure the safe handling and transport of electronic products.

✔️ Lubrication in Polymer Processing for Circuit Boards

Magnesium Stearate is used in the lubrication of polymer materials during the manufacturing of circuit boards and other electronic components. It reduces friction and heat generation, promoting seamless processing and preventing damage to delicate electronic structures.

Magnesium stearate’s compatibility with polymers ensures optimal production efficiency and quality.

👉 Innovations and Future Possibilities of Magnesium Stearate

☑️ Advancements in Manufacturing Techniques and Purity

Ongoing research and advancements in manufacturing techniques continue to improve the purity and performance of Magnesium Stearate. Efforts to reduce impurities and enhance its functionalities open doors for innovative applications and increased utilization across industries.

☑️ Novel Applications and Industry-specific Product Development

Magnesium Stearate presents opportunities for novel applications and industry-specific product development. The exploration of its properties and interactions with various materials unlocks possibilities for tailored formulations, enabling optimized performance and addressing specific industry needs.

☑️ Potential Challenges and Opportunities for Further Research

While Magnesium Stearate offers numerous benefits and potential innovations, challenges and opportunities for further research persist. Studying its impact on specific industries, investigating potential alternatives, and addressing any concerns would further enhance its usage in a safe, sustainable, and effective manner.

Magnesium stearate’s versatility and functionality make it an essential ingredient across diverse industries. Its lubricating properties, hydrophobic nature, and stabilizing effects make it vitally important in most of the industries.

As a buyer, understanding its properties, applications, and factors to consider will empower you to make informed decisions when purchasing Magnesium stearate for the needs of your business. Choose Sakha International as your supplier as we offer high-quality products and excellent customer support to ensure the success of your projects and applications.