WHAT MAKES SAKHA INTERNATIONAL THE LEADING

BULK DISTRIBUTOR OF ZINC OXIDE

ZINC Oxide : A Comprehensive Guide for Buyers

👉 Zinc oxide, a versatile compound with numerous applications, is primarily known for its sun protection properties. However, its uses span far beyond skincare. This article will delve into the world of zinc oxide, exploring its manufacturing process, the importance of selecting a reliable supplier, and the key factors that contribute to the best quality of zinc oxide.

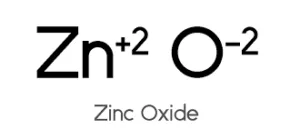

🤔 What is Zinc Oxide❓

✔️ Zinc oxide, a crucial metallic compound, holds immense significance in multiple industries. It is formed through the process of oxidizing zinc metal, resulting in the creation of a fine ⚪white powder. This versatile compound exhibits significant qualities that make it indispensable for numerous applications.

👍 Uses of Zinc Oxide

1️⃣ The Cosmetic Industry

Zinc oxide is highly favored in the cosmetic industry for its beneficial properties. The compound acts as a natural sunscreen, providing protection against harmful ultraviolet (UV) rays. Additionally, its anti-inflammatory properties make it an ideal ingredient for skincare products, helping to soothe irritated skin conditions.

2️⃣ The Rubber and Tire Industry:

With its excellent heat resistance, zinc oxide is extensively utilized in the rubber and tire manufacturing sector. This compound aids in the production of high-quality rubber products, imparting strength and durability.

Zinc Oxide is also widely used in FOOTWEAR INDUSTRY.

3️⃣ The Ceramic Industry:

In the ceramic industry, zinc oxide serves as a fluxing agent, promoting the fusion of materials during the firing process. This results in improved durability and glaze quality of ceramic products.

4️⃣ The Paint and Coatings Industry:

Zinc oxide plays a vital role in the paint and coatings industry due to its exceptional UV-blocking capabilities. It acts as a shield against sun-related damage, extending the lifespan of painted surfaces.

👨🚒 Selecting a Reliable Zinc Oxide Manufacturer

✔️ Quality Assurance:

When choosing a zinc oxide manufacturer, it is crucial to prioritize quality assurance. Look for manufacturers who adhere to stringent quality control processes, ensuring consistent and reliable product standards.

✔️ Manufacturing Capabilities:

Opt for a manufacturer that possesses advanced manufacturing facilities equipped with cutting-edge technology. This ensures efficient production processes and guarantees a steady supply of zinc oxide.

✔️ Sustainable Practices:

Consider manufacturers who prioritize environmental sustainability by implementing eco-friendly production methods. This showcases a commitment to reducing the ecological impact without compromising on product quality.

🏭 Applications of Zinc Oxide in Various Industries

1) Zinc Oxide in the Agricultural Industry:

In agriculture🌳, Zinc Oxide finds widespread use as a micronutrient fertilizer. It rectifies zinc deficiencies in soil, ensuring optimum crop growth and productivity. Zinc Oxide’s ability to enhance the uptake of vital nutrients by plants is a boon for farmers worldwide. Additionally, its fungicidal properties aid in controlling fungal infections, safeguarding crop yield and quality.

2) Zinc Oxide in the Pharmaceutical Industry:

In the pharmaceutical industry,💊 Zinc Oxide plays a vital role in various applications. Its antiseptic properties make it a popular choice for wound healing creams, ointments, and bandages. Moreover, Zinc Oxide is an essential ingredient in numerous dermatological products due to its soothing and protective effects on the skin. Its antimicrobial and astringent properties also contribute to its effectiveness in treating acne and other skin conditions.

✔️ Advantages and Disadvantages of Zinc Oxide Application

👍 Advantages of Zinc Oxide

1) UV Protection: Zinc oxide is renowned for its exceptional capability to shield against harmful ultraviolet (UV) rays.

2) Wound Healing: Due to its antimicrobial and anti-inflammatory properties, zinc oxide aids in the healing process of wounds.

3) Skin Soothing: Zinc oxide is gentle on the skin and possesses a soothing effect.

4) Low Toxicity: Zinc oxide exhibits low toxicity levels, making it safe for humans and the environment when used appropriately.

5) Corrosion Prevention: When employed as a corrosion inhibitor, zinc oxide acts as a protective barrier on metal surfaces, safeguarding them from rust and corrosion.

👎 Disadvantages of Zinc Oxide

1) Environmental Impact: Although zinc oxide is generally safe for the environment, excessive discharge into water bodies can have adverse effects on aquatic life, especially if the compound reaches high concentrations.

2) Potential Health Concerns: Inhalation of zinc oxide in its fine powder form should be avoided as it may lead to respiratory issues.

3) Absorption-Related Concerns: While zinc oxide is considered safe for skin application, there have been reports of potential absorption through the skin.

4) White Cast Appearance: Zinc oxide, when used in certain concentrations in sunscreens or other topical applications, may leave a white cast on the skin.

📈 Zinc Oxide Production and Market Analysis

✍️ Overview of Zinc Oxide:

Zinc oxide, a compound composed of zinc and oxygen, has an extensive range of applications across multiple industries. With its remarkable properties and versatility, zinc oxide has become a vital component in various manufacturing processes.

Zinc Oxide Production Methods:

- Direct Process:

The direct process of zinc oxide production involves the combustion of zinc vapor in the presence of air. This method yields high-quality zinc oxide and is employed mainly for cosmetic and pharmaceutical purposes. - Indirect Process: In the indirect process, zinc oxide is produced by the oxidation of zinc-containing materials, such as zinc ores or recycled zinc. This approach is commonly used for industrial applications, including rubber manufacturing, ceramics, paints, and coatings.

Market Analysis:

The global market for zinc oxide has experienced substantial growth over the years, driven by its diverse applications and increasing demand in key sectors. Several factors contribute to the market’s expansion:

Rubber Industry:

Zinc oxide plays a pivotal role in the rubber industry, where it is utilized as an essential additive. Its exceptional properties, such as UV protection, heat resistance, and anti-aging characteristics, make it an ideal component in the manufacturing of rubber goods, including tires, footwear, and industrial rubber products.

Cosmetics:

Within the cosmetics industry, zinc oxide is widely employed due to its excellent sun protection abilities. The compound acts as a physical sunscreen, effectively blocking harmful UV rays from reaching the skin. Additionally, zinc oxide is known for its skin-soothing and anti-inflammatory properties, making it a common ingredient in various skincare products.

Pharmaceuticals:

Zinc oxide is extensively used in pharmaceuticals, including ointments, creams, and powders, due to its antiseptic and wound-healing properties. Its ability to protect and soothe the skin makes it an integral component in various medicinal applications.

Ceramics:

In the ceramics industry, zinc oxide is utilized for its low-melting properties. It acts as a flux, reducing the temperature required for glazing and improving the overall firing process. Moreover, zinc oxide enhances ceramic products’ brightness and consistency.

✔️ When it comes to zinc oxide production, choosing a reputable manufacturer is crucial to ensure superior quality. Trusted manufacturers employ advanced techniques and adhere to strict quality control measures.

As a buyer, understanding its properties, applications, and factors to consider will empower you to make informed decisions when purchasing Zinc Oxide for your specific needs. Choose a reputable supplier that offers high-quality products and excellent customer support to ensure the success of your projects and applications.

At SAKHA INTERNATIONAL, we make sure to provide the best quality ZINC OXIDE in the best possible prices. We have trained staff for each product who are skilled to understand the need and requirements of our customers and then refer them the quality accordingly.

If you want the best quality Zinc Oxide at least possible process Call us today at 9810055405/9312455405.

FAQs About Zinc Oxide❓

Q What is Zinc Oxide?

Zinc Oxide, also known as ZnO, is a white, powdery compound derived from the element zinc. It is created through the oxidation of zinc metal, resulting in a fine powder with excellent properties.

Q: How is Zinc Oxide manufactured?

Zinc Oxide is primarily manufactured by two methods: the indirect (French process) and the direct (American process). The French process involves the heating of metallic zinc in the presence of air, while the American process utilizes the combustion of zinc vapors generated from a furnace.

Q: What are the properties of Zinc Oxide?

Zinc Oxide possesses unique characteristics that make it highly desirable in various applications. It exhibits excellent UV-blocking capabilities, making it an essential ingredient in sunscreens. Additionally, it has antimicrobial properties, acts as a catalyst, and provides excellent electrical conductivity.

Q: Is Zinc Oxide safe for human use?

Yes, Zinc Oxide is considered safe for human use. It has been extensively tested and approved by regulatory bodies worldwide, including the FDA. It poses no significant health risks when used as directed in various applications.

Q: What are the environmental impacts of Zinc Oxide usage?

Zinc Oxide is considered environmentally friendly due to its low toxicity and non-hazardous nature. It does not contribute to air, water, or soil pollution when used in controlled quantities. However, proper handling and disposal should still be adhered to in order to minimize any potential environmental impact.